In the industrial

finishing process, what you don’t paint is as important as what you do paint.

Threads, studs and crucial surface areas need to be effectively masked. That

masking needs to be suitable for low to high pressure treatments as well as

high temperature environments such as powder and E-coating finishes.

The cost implications of

leaks, cracks and other failures can be catastrophic. Taping can be time

consuming both to apply and remove and ineffective on repeat processes.

Choose from a wide

variety of standard caps, plugs and custom shapes, all of which are available

in materials and lengths to suit your application.

Many sizes are held in stock. But we also specialise in medium to high run

bespoke manufacturing in house, designed to your specifications.

Flexible Short Caps, for

instance, can be applied quickly and easily. No matter what the application,

they fit snugly without cracking or splitting. Short Caps also possess

excellent insulation qualities and resist weather, moisture and chemicals.

Applications include:

- Thread Protectors

- Masks (for painting, plating, powder coating, shot blasting)

- Insulators

- Decorators

- Seals

- colour Coding

The tapered plug design

of these plugs allows one size to fit multiple ports while the soft rubber

material conforms to provide a tight seal. EPDM

plugs are ideal for most plating and anodizing applications due to their

excellent resistance to chemicals.

Using the right caps or plugs for the

right job is essential.

It is important to fully understand the

customers’ needs in order to suggest the most appropriate and cost effective

solutions. If, for some reason, we can’t visit the site, then photographs and

technical drawings of the component and the areas that need protecting do help our

own engineers to plan, structure and cost our proposals.

What are we protecting the crucial parts

from? What are we keeping out and what are we keeping in? What temperatures and

materials are the parts going to be exposed to during the rigorous finishing

stages of their life?

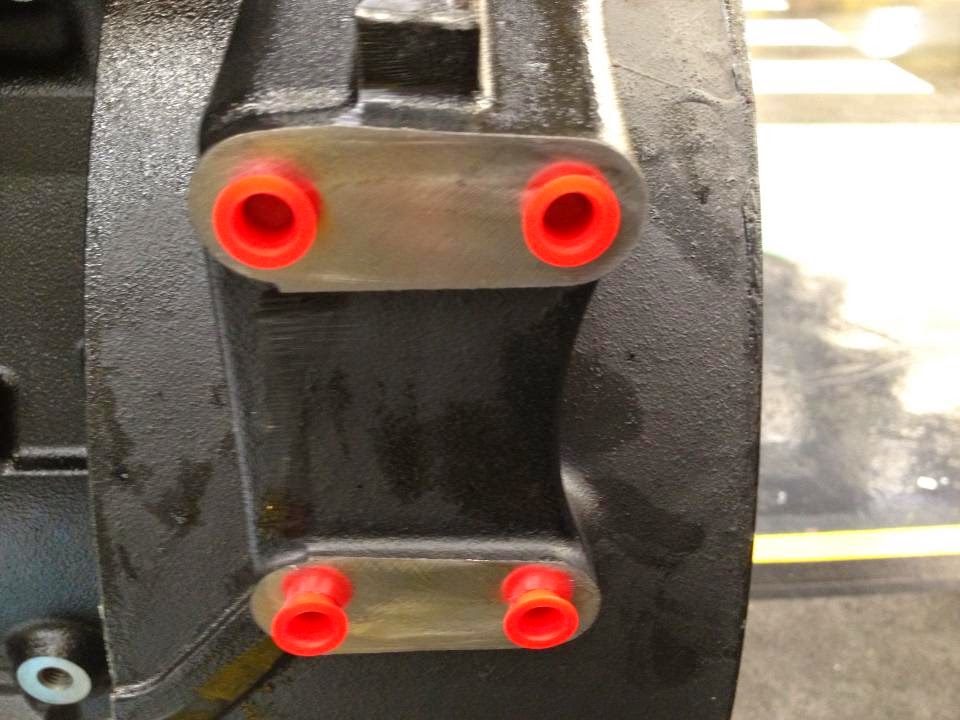

We have many 'off-the-shelf' solutions in the form of caps and plugs such as the plastic plugs on the engine mounting

(above) protecting the threads from abrasive dirt ingress. However, with some

lateral thought from our custom moulding engineering department, instead of

applying five plugs before steam cleaning the unit, the fast application and

removal of a multiple plug speeds the process up enormously (below).

This plastic diaphragm has been designed to

protect the engine module as it is shipped from a manufacturer in the UK China

… A combined cap / plug diaphragm like this is

clearly not an off-the-shelf product, but the result of combined, creative,

engineering skill to create a solution that has become integral in an extended

and global manufacturing process.

Whether you simply want a low order quantity of

flexible caps from stock, or have a bespoke application that needs a

cost-effective solution, just pick up the phone and we'll be pleased to help.

Call now for expert advice on

01634 686 504 or take a look and buy on-line through the Shop Now button below:

01634 686 504

FLAT CABLE END SEAL REQUIRED

ReplyDelete