Life in the fast lane can be a pretty rough ride for your goods in

transit.

Finished effectively and protected

en route, the same QC stamp of approval will apply to goods reaching your

customers as proudly as it did when leaving your work – and this is where

S&R can help.

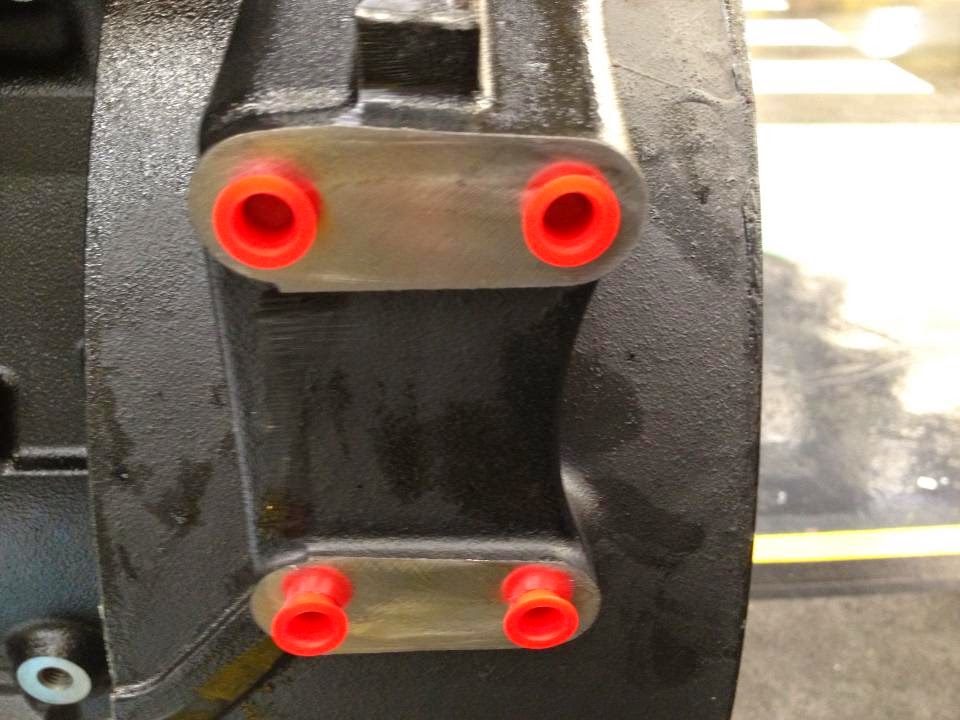

[Click on any of the images below to find out more of the many options available from S&R]

Sinclair

& Rush’s remit is to manufacture and supply products that Protect, Package

and Finish our customers’ wide ranging materials, products and work in

progress. This week we are spotlighting two product ranges that do just that:

Plastic and Rubber Edging protects

and finishes sharp, fragile, brittle edges.

Plastic Netting protects packaged

product and WIP in transit.

Edgings

strips have a huge range of applications and, as such, are available in an

equally huge variety of materials, strengths and formats.

The

simplest is the standard plastic edge which protects sharp and vulnerable

edges. It is durable and flexible enough to clip over irregular shapes. These

strips are available in 10, 25 and 50 metre lengths which you simply cut to

size and apply.

Heavier duty edging strips offer extra protection & durability

to provide a neat and safe finish to sharp or brittle edges. These too are

available in handy 10, 25 and 50 metre lengths.

Foam edging strips or Edge protectors are prized by the transport

industry for protecting products and goods during transportation. As well as

being excellent for shipping protection, the foam edge can be used to protect

any number of corners and crevices. The edge protector can be used for carrying

sheet metal or glass, table tops, protect desk edges, painting protection,

fragile goods, MDF, general edge protection etc.

Impact protection profiles provide both a visual warning and a

safety cushioning. They protect corners, protruding edges and goods in

warehouses, production areas etc. These high quality foam edging protectors are

fitted with a self adhesive strip for easy installation to a smooth, dust and

grease free surface and are manufactured in flexible age-resistant polyurethane

foam.

Protective Netting is as flexible and practical as it sounds.

It comes in ‘long’ tubes of netting and a variety of strengths.

There is also a ‘high stretch’ format that fits easily around irregular shapes.

So there is something for every application.

To

minimises surface scratching, scuffing & indentations, plastic netting is

the perfect solution. It can be cut to your exact size or supplied in longer

lengths on reels, so that you pull and cut the length you need for the job at

hand. It reduces packaging & shipping costs and is available in low minimum

order quantities.

Pallet Netting is increasingly

popular. It creates friction to help hold loads in place providing an additional

protective layer when shipping that neither rots nor rusts.

As

we said though – the applications are so varied and the products to Protect,

Package and Finish so broad that the best way to find out more is to call our

experts on 01634 686 504 or to look at the range and shop on-line here.

01634 686 504